What’s the Difference Between Foil Stamping, Letterpress and Embossing?

In commercial printing, there’s a whole raft of bespoke finishes and embellishments to choose from—especially if you’re looking for ways to add to the perceived value of your print project. Be it an order of invitations, business cards, stationery, packaging or a fancy promotional brochure, embellishment takes those creative elements from ordinary to extraordinary. Why? Because unlike your average piece of print, embellishments offer consumers an irresistible, three-dimensional experience of touch.

Foil stamping, embossing and letterpress are among the fancyworks of choice, but many people will confuse the three processes as pressure and plates are used in all three. Nonetheless, each finish yields a vastly different result.

In this guide, you’ll learn the difference in techniques and how to use them in your artwork. Once you’ve established the sensory contrasts between each of our processes, your newfound air of confidence will have you gliding through the prepress phase. What’s more, you’ll gauge a better understanding of what to expect come delivery.

Still, our print jargon is no mean a feat for the faint-hearted. So, if you find yourself overwhelmed by the various terms, not to mention the subtle nuances of each method applied, you’re not alone. There’s a reason we have dedicated account managers at Bambra. And this is why you should engage your print experts to help explain the specialist techniques in a way that makes sense to your designs.

Foil Stamping

For something a little bit special, there’s metallic foiling. This example is so good, you’d think it was liquid gold (design & photo by our wonderful client, Arctic Mirage).

Hot foiling or foil stamping is for those clients who desire a little touch of opulence to take their print project further into high-end territory. Particularly used for heavier paper stocks, it’s the kind of embellishment that makes for an enticing piece of print you want to pick up and read. Heat, pressure and stamping foil are used to apply a logo or other design to paper. This creates an inimitable finish that refracts light. Specialty foiling blocks are custom-made and applied by our expert craftsman to create foiling effects.

Over the years we’ve produced plenty of standout projects with the addition of foil. Letterheads, invitations, certificates, business cards, stickers and brochures are frequently garnished by our premium-grade blocks. But we also use foiling on products that consumers respond best to by touch—like menus, product tags and gift vouchers. Metallic foiling is our most-popular finish, but we also have matt foiling which is used to create a smooth, satin-like surface without the sheen. For a great alternative to a spot UV finish, there’s the option to add a touch of gloss to your design with clear foiling.

Letterpress

The iconic Stokehouse Restaurants enlisted Bambra to print these very impressive letterpress gift vouchers.

Letterpress is one of the oldest forms of printing that exists. Like foil stamping, it’s a process that uses specially-made blocks and pressure to imprint a design. But instead of using foil, our original Heidelberg Platen Press applies ink to create its third-dimension. Not only does this type of embellishment look and feel superb, it also ensures your project leaves a lasting impression no matter how simplistic the design. Think wedding invitations, swing tags, with compliments and the most outstanding business cards to show off those modern, sophisticated lines in your design.

Letterpress transcends the average print marketing experience because it plays on our senses and feelings of nostalgia. It’s no wonder this process has made a comeback in recent times. Though it takes a great deal of skill to master the traditional craft of letterpress, our operators have years of expertise up their sleeves.

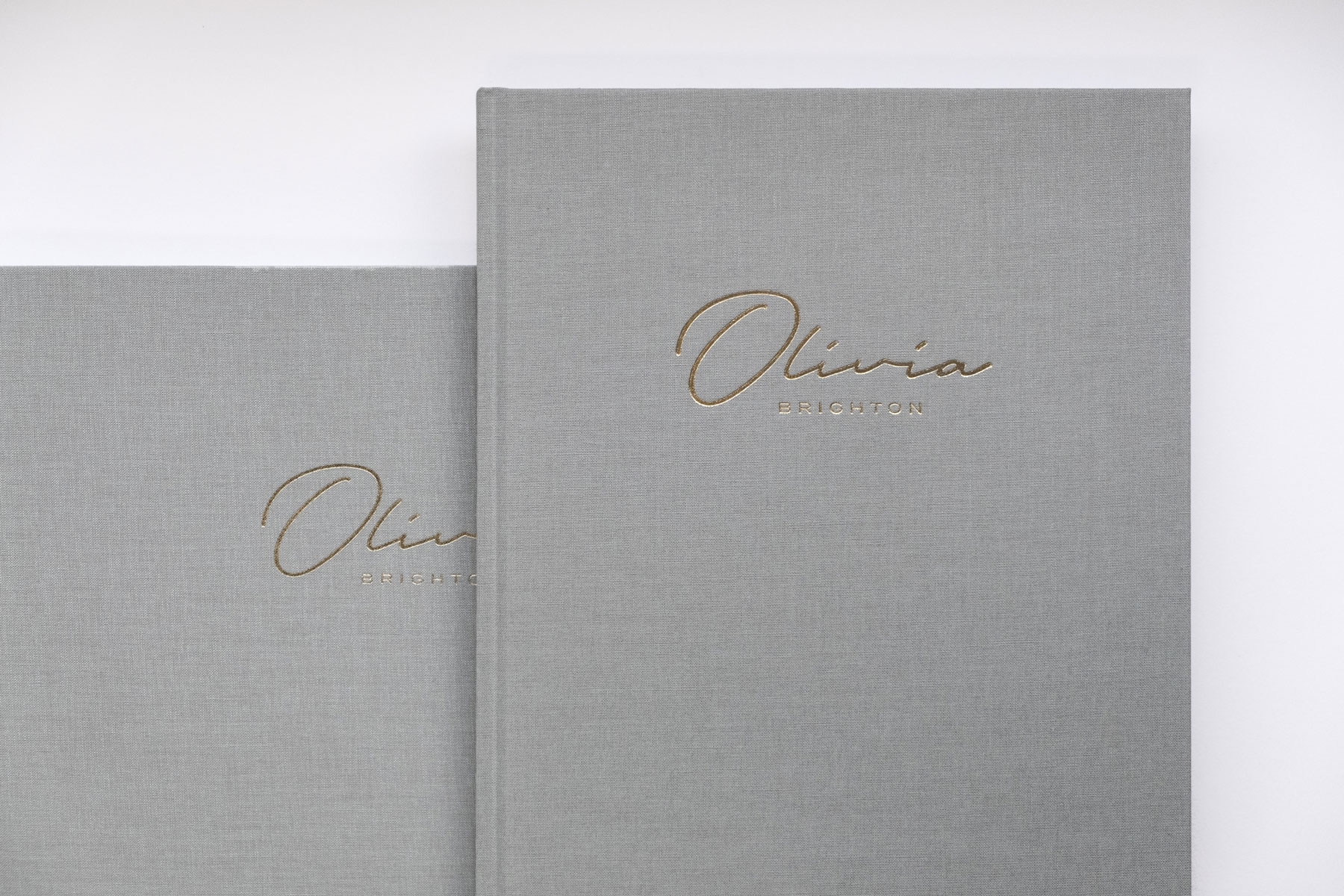

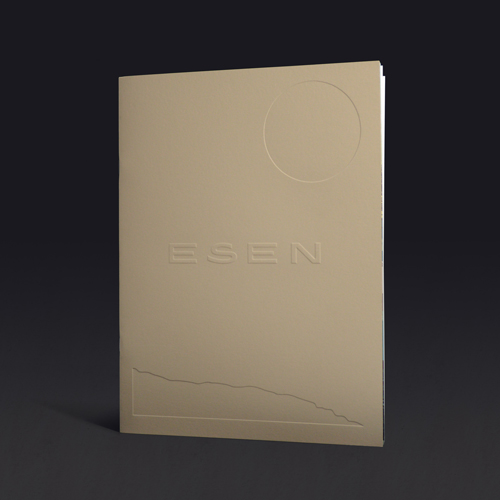

Embossing and Debossing

Designed by Seesaw Studio, this beautiful brochure is a fine example of what embossing and debossing can do for your designs.

Brilliance was never born out of mediocrity. If you want to make your mark minus the ink, embossing and debossing is an impressive feature to add to your paper, card stock or another choice of material. Like foil stamping and letterpress, embossing and debossing use heat, pressure and plates. The difference is that these processes involve a blind (without ink) impression to create depth or height. Think of it like a heavy stamp, where debossing creates a recessed effect, and embossing creates a raised effect.

Multiple logo dimensions or bevelled edges are a welcome addition to any brochure, invitation or stationery spread. Who knew something so simple as an inkless impression on the surface of a cover could appear so striking?

Whichever way you choose to package your premium print projects, capturing the attention of the receiver comes down to those details. Bambra’s finesse for embellishments, like foiling, embossing and letterpress, might just be the lucrative card you’ve been meaning to play. Contact the leaders in premium print to let your next project speak volumes about your brand.

Latest News

Judge A Book By It’s Cover

At Bambra, we know a book’s cover is just as important as what’s inside. That’s […]

Earl, meet Wanda

Alrighty, paper enthusiasts! We’re thrilled to announce that we’ve just redesigned and launched our new […]

Big, Bold, Beautiful. Wide Format Printing at it’s best.

When it comes to wide format print projects, having the right tools is absolutely essential. […]

Bambraology. Drip Off Varnish Explained.

THE WHAT. So, what exactly is a Drip Off? It’s a varnish technique (also […]